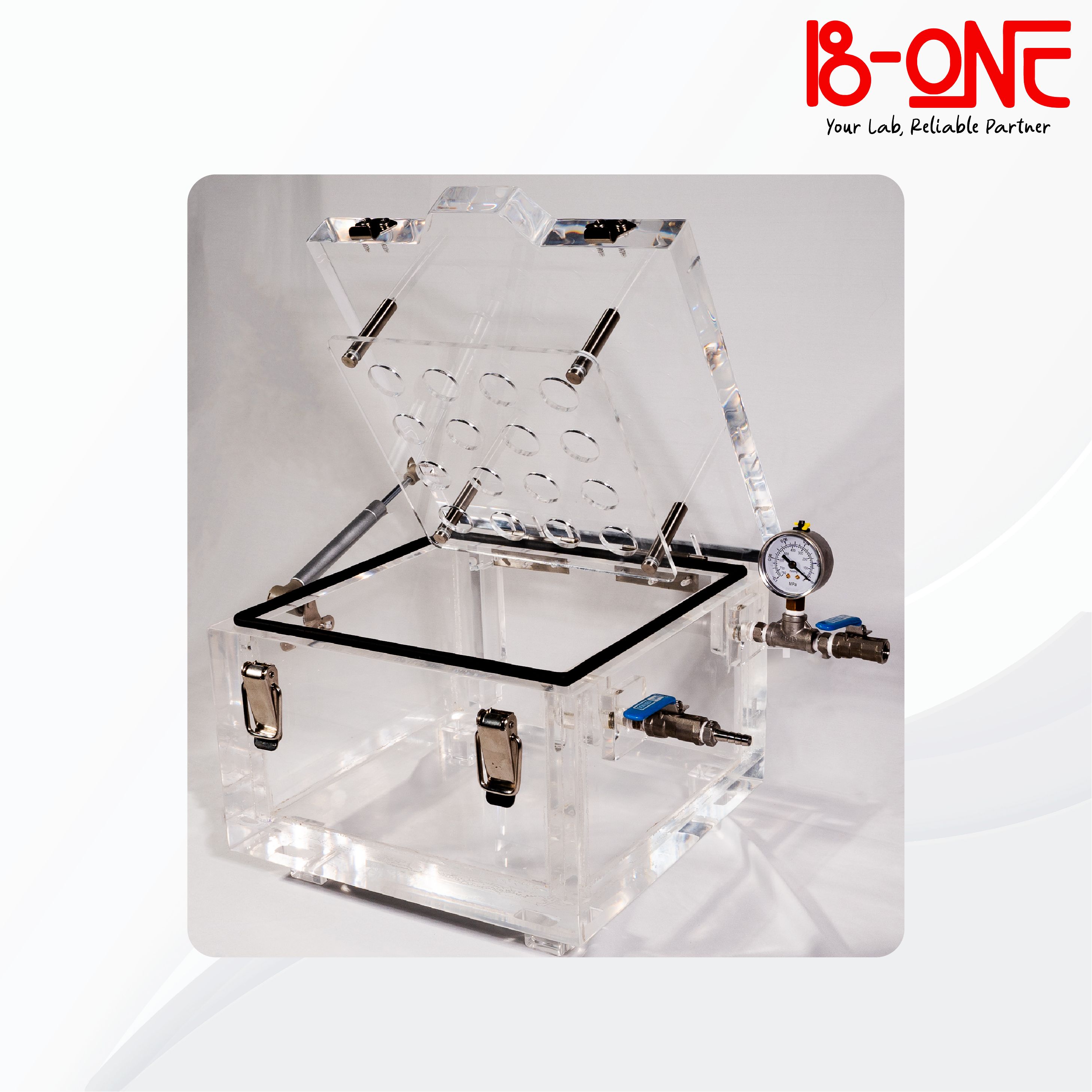

B-ONE Vacuum Leak Tester

Vacuum leak tester is a laboratory device used to detect leaks or weak seals in containers, packaging, or other sealed items. It works by creating a vacuum around the test item and monitoring for any changes in pressure or the appearance of air bubbles, which indicate a leak. Vacuum leak testers are widely used in industries like pharmaceuticals, food packaging, electronics, and manufacturing to ensure product integrity and quality.

How a Vacuum Leak Tester Works

- Vacuum Chamber: The item to be tested is placed in a vacuum chamber.

- Vacuum Generation: A vacuum pump removes air from the chamber, creating a low-pressure environment around the test item.

- Pressure Monitoring: The tester monitors pressure levels. If there’s a rise in pressure within the chamber or if bubbles appear (for tests involving liquids), it indicates that air is leaking from or into the item, meaning there’s a flaw in its seal.

- Test Results: If no leaks are detected, the item passes the test; otherwise, it fails, indicating the need for adjustments to ensure a proper seal.

Types of Vacuum Leak Tests

- Bubble Test: Often done with liquid, where the test item is submerged, and bubbles indicate leaks.

- Pressure Decay Test: Monitors changes in pressure over time to detect any leakage.

- Tracer Gas Test: A tracer gas, such as helium, is introduced, and any escape is detected using sensors.

Applications of Vacuum Leak Tester

- Pharmaceutical Packaging: Ensures that medications are stored in airtight containers to prevent contamination and maintain efficacy.

- Food and Beverage Packaging: Tests vacuum-sealed and airtight packaging for leaks, which could compromise shelf life and product quality.

- Medical Devices: Checks the seals on sterile packaging for devices or implants to ensure sterility.

- Electronics: Verifies the hermetic seals on sensitive electronic components, preventing exposure to moisture or other contaminants.

- Automotive and Aerospace: Detects leaks in fuel systems, brake systems, and other critical components that require a sealed environment.

Benefits of Using a Vacuum Leak Tester

- Cost-Effective: Early detection of leaks reduces waste and rework, saving costs in the long run.

- Ensures Product Integrity: By confirming airtight or watertight seals, vacuum leak testers help maintain product quality.

- Quality Control: Essential for maintaining standards and meeting industry regulations, especially in pharmaceuticals and food.

Check out B-ONE Vacuum Leak Tester products with low price here

Contact B-ONE:

Whatsapp: +62 812-9777-2400

Email: sales@priolab.id